Price Is Easy to Compare — Risk Is Not

When sourcing peel and stick tiles, retail buyers often focus on unit price and design. While these factors matter, most long-term problems come from details that are not obvious during initial sampling.

From a supplier’s perspective, many issues that lead to returns or complaints could have been avoided earlier in the sourcing process.

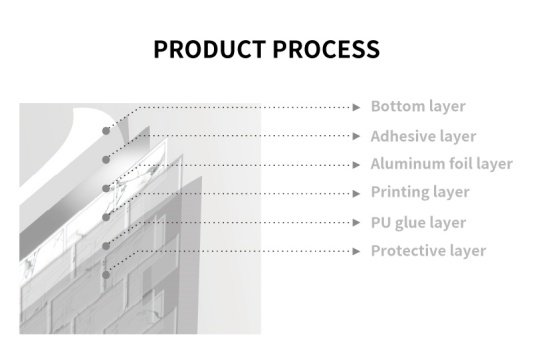

Material Structure Matters More Than Appearance

Two tiles may look identical on the surface but perform very differently in real use.

Buyers often overlook:

- Base material stability

- Layer structure consistency

- How materials respond to humidity and temperature changes

Without understanding the internal structure, it is difficult to predict long-term performance—especially in kitchens and bathrooms.

Adhesive Performance Is About Balance, Not Strength Alone

“Strong adhesive” sounds reassuring, but strength alone is not the goal.

Retail issues often arise when adhesive is:

- Too weak, causing edge lifting

- Too aggressive, leaving residue or wall damage

A well-balanced adhesive system should hold securely while still allowing clean removal when needed. This balance is critical for rental and retail-focused products.

Packaging and Instructions Are Often an Afterthought

Many retail complaints are not caused by product failure, but by incorrect installation.

Buyers frequently underestimate the role of:

- Clear installation instructions

- Surface preparation guidance

- Accurate coverage and usage information

Well-designed packaging reduces misunderstandings, lowers return rates, and improves overall customer satisfaction.

Batch Consistency Is Rarely Checked Early Enough

Sampling usually represents the best production batch, not everyday output.

Retail buyers often forget to verify:

- Color and texture consistency across batches

- Adhesive stability over time

- Ongoing quality control standards

Inconsistent batches can quickly damage retail trust, even if the initial samples performed well.

Supplier Capability Goes Beyond Manufacturing

A reliable peel and stick tile supplier does more than produce tiles.

Key factors buyers sometimes overlook include:

- Production capacity during peak seasons

- Communication efficiency when issues arise

- Willingness to optimize products based on market feedback

Long-term cooperation depends on operational reliability, not just product specs.

Final Thoughts for Retail Buyers

Successful sourcing of peel and stick tiles requires looking beyond price and appearance.

By paying attention to material structure, adhesive balance, packaging clarity, batch consistency, and supplier capability, retail buyers can significantly reduce risk and build more sustainable product lines.

🔗 Internal link suggestion: Peel & Stick Tiles Category / Contact Us